[1] Source: Deloitte study – TIP 2019 – 45 countries

[2] “Global ELT Management – A global state of knowledge on regulation, management systems, impacts of recovery and technologies”, WBCSD & Tire Industry Project

Ever wondered what happens to your old tyres when you get them replaced? Below we explore the reality behind car tyre recycling and how Michelin works to promote their recycling, while constantly striving to reduce the environmental impact of its own products.

Whether you’re driving the daily commute or taking epic cross-country trips on weekends, after enough time on the road, your car tyres eventually start to show signs of wear. Once your tyres reach a tread depth of 1.6mm, you need to replace them to ensure maximum safety on the road, as well as remaining law compliant.

Sometimes you may need to swap them out sooner due to damage, punctures... This car tyre disposal leads to around 30 million tons of tyres[1] being replaced and potentially thrown away every year, worldwide!

But what if we told you that car tyres can be recycled? The tyre industry is actually one of the most advanced sectors in end-of-life product management. Approximately 88%[2] of end-of-life tyres are now collected, the majority of which are recovered , which is pretty impressive when you consider that only 14% of plastic packaging[2] is converted through recycling.

Before the tyre recycling phase, Michelin is taking action at every stage in the lifecycle of its products to reduce its environmental impact.

Although they may look simple, car tyres are actually made of over 200 different materials. These include natural and synthetic rubber, carbon black and silica, reinforcing fillers, steel and textile reinforcements, and chemical agents.

Most car tyres consist of different layers, which adds another level of complexity to the tyre recycling process as manufacturers like Michelin work on developing innovative new methods and technologies to facilitate the reuse of all the different elements. These car tyre layers usually integrates synthetic rubber, textile fibre cords, metal cords, ...

The rubber tyre recycling process often begins at the dealer’s, when you bring in your car to have the old, worn-out tyres replaced.

You can also take your tyres to a tyre recycling plant, or household waste recycling centres. However, there may be a limit to how many you can take, and you may also be charged.

Michelin is actively contributing to the development of the tire recycling industry by becoming involved in tire collection systems in many countries around the world.

The Michelin group is investing in tyre recycling and developing innovative, breakthrough technologies in collaboration with its partners in order to transform worn tyres or waste into regenerated raw materials.

Need new tyres? Find a MICHELIN tyre dealer near you :

Car tyre disposal via recycling or car tyre recycling is just one of many ways that we can work together to reduce the environmental footprint of a tyre’s lifecycle, from manufacturing to end-of-life.

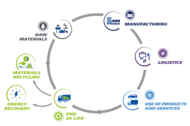

Michelin uses eco-design principles to limit the environmental impact of its tyres at every stage in their lifecycle, from the supply of raw materials and production to the use and recycling phases.

As part of its All-Sustainable approach, Michelin is taking action within the industry alongside its stakeholders and industry partners to promote tyre recycling while constantly striving to reduce the environmental impact of its products. By 2050, it aims to have tyres made from 100% sustainable materials, while also improving the tyre energy efficiency by 10% in 2030 compared to 2020.

Reducing its impact doesn’t just stop there – Michelin is also optimising transport logistics, designing tyres that reduce fuel and energy consumption, just like the MICHELIN e·PRIMACY tyre, and working with other manufacturers to develop cutting-edge new recycling processes that will help transform waste into raw materials.

This circular economy approach is characterized by Michelin’s 4Rs approach: Reduce, Reuse, Recycle and Renew.

By raising awareness and helping to limit the environmental impacts associated with end-of-life tyres, Michelin aims to develop the recycling sector around the world. In Chile, for example, Michelin is building its first earthmover tyre recycling plant, where an end-to-end experience will be offered, i.e collecting old tyres and reusing regenerated materials.

Find out more on the Group’s Sustainable Development and Mobility strategy that aims to make Michelin one of the most innovative, responsible, and high-performing companies worldwide across all of its responsibilities: economic, environmental, social and societal on michelin.com.

Sources

[1] Source: Deloitte study – TIP 2019 – 45 countries

[2] “Global ELT Management – A global state of knowledge on regulation, management systems, impacts of recovery and technologies”, WBCSD & Tire Industry Project